Horizontal IXPE foam

Irradiated cross-linked polyethylene foam (IXPE)

IXPE Foam made by high-temperature foaming after electron accelerator for irradiation, followed by extrusion of melted low-density polyethylene (LDPE), AC foaming agent and other powders.

Product specification:

Density: 25~330Kg/m^3

Ratio Times: 2~40

Thickness: 3~15mm(single layer) to 80mm (multilayer)

Width: 600~2400mm

Shore hardness: 13~70°

Water absorption, 23+2°C,24h : 0.2~0.5%

Thermal conductivity: 0.040~0.095w/m.k

CYG TEFA Products

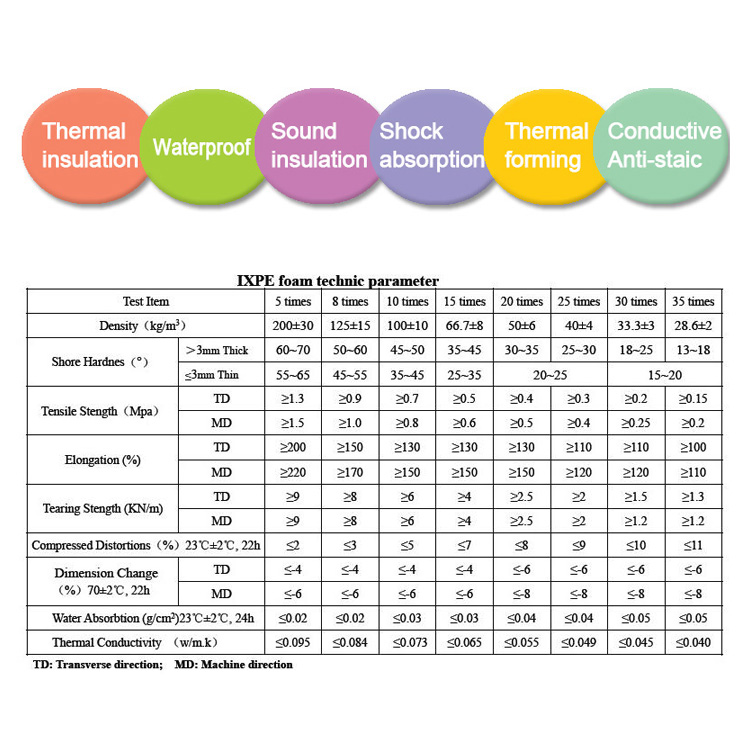

IXPE Foam Features

1. Rolled products, the thickness ranges from 3.0~10mm (single layer) to 100mm (multilayer)

2. With flame resistance function (UL 94 HF-1 & FMVSS 302)

3. Provide different grades of products, diversified soft and hard choices and a variety of special functions

4. Uniform closed cell structure

5. Working temperature (-40℃~80℃, up to 120℃ for special specifications)

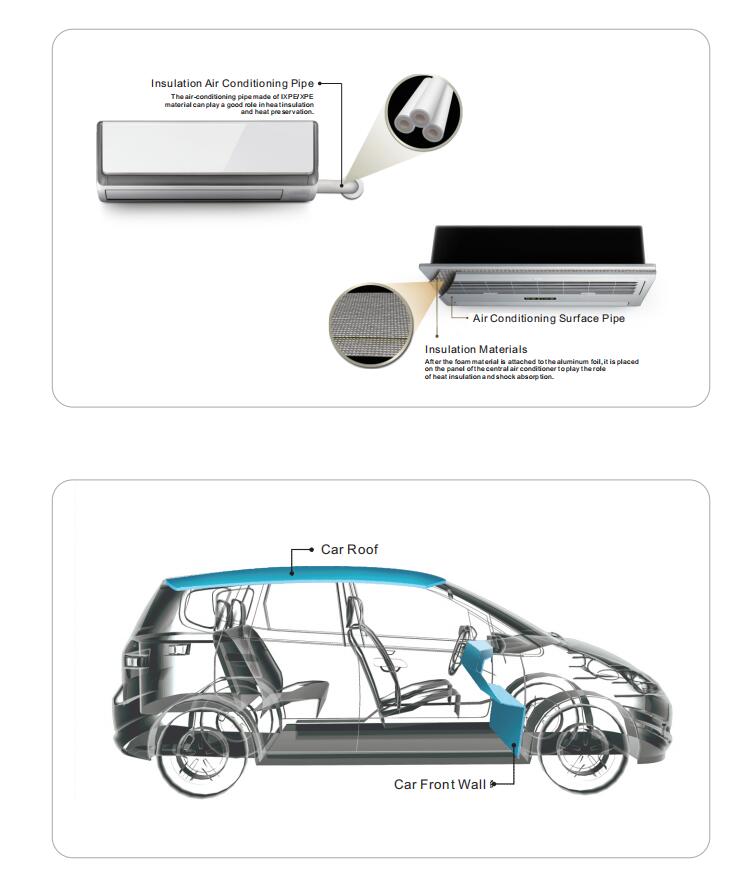

6. High-performance heat insulation and heat preservation materials

7. Superior sound insulation performance

8. Very low water absorption and water vapor permeability

9. High quality and long life

10. Good anti-chemical properties

11. Suitable for thermoforming and vacuum forming

12. Non-toxic, odorless, non-volatile

13. Comply with EU RoHS regulations

14. No chlorofluorocarbons (such as CFCs, HCFCs) are used in the process

CTF Service provided:

| a. | General specification products |

|---|---|

| b. | Flame-resistant products, comply with UL 94 HF-1 & FMVSS 302, and RoHS specifications |

| c. | Conductive products |

| d. | Anti-static products |

| e. | Antibacterial products |

| f. | Thermal insulation products |

| g. | Sound insulation products |

| h. | Waterproof products |

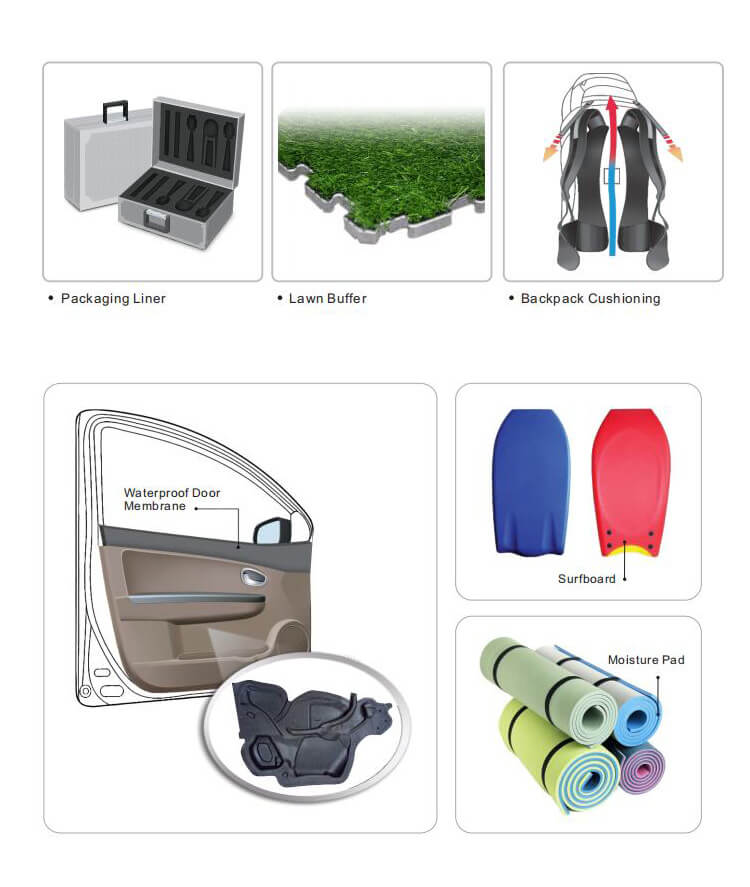

| i. | Shock absorption products |

| j. | Anti-UV products |

| k. | Provide good thermoforming ability |

| l. | Provide good compression distortion and thermoforming ability |

| m. | Post-progressing: with texture; lam ination; aluminum foil(other requirements you may demand) |

| n. | PP products |