PE/ XPE/ IXPE/ IXPP/ ESD foam industry news

CYG TEFA CO., LTD Showcases Advanced Foam Solutions at Foam Expo Europe 2023

Stuttgart, Germany – CYG TEFA CO., LTD is pleased to announce our successful participation at Foam Expo Europe 2024, held in Stuttgart from [Event Dates]. Our overseas sales department represented us at Stand 237 during this prestigious industry event.

CYG TEFA is a globally recognized leader in the design and production of advanced foamed materials, delivering exceptional safety and comfort solutions across various industries. Our diverse Business Units offer an extensive range of products and solutions tailored to meet specific market needs.

Foam Expo Europe provided an excellent platform for us to showcase our latest innovations and engage with industry professionals and customers. Attendees had the opportunity to explore our cutting-edge foam technologies designed for automotive, aerospace, packaging, and other applications.

We extend our gratitude to everyone who visited Stand 237 and expressed interest in our foam solutions. Your support and enthusiasm contribute to our continued success in advancing foam technology.

For more information about CYG TEFA and our innovative foam solutions, please visit CYGTEFA.COM.

About CYG TEFA CO., LTD

CYG TEFA CO., LTD is a leading manufacturer specializing in the development and production of advanced Cross linked Polyolefins Foam materials. With a global presence and a commitment to innovation, we offer a wide range of foam products designed to enhance safety, comfort, and performance across diverse industries.

XPE foam and EVA foam are both types of closed-cell foam materials commonly used in various industries.

Here are some differences between the two:

Fust, XPE foam and EVA foam can be visually distinguished by their appearance.

XPE foam has a more uniform, closed-cell structure with a smoother surface, while EVA foam has a more open-cell structure with a rougher surface. XPE foam is also typically thicker and denser than EVA foam.

Material Composition: XPE foam is made of cross-linked polyethylene foam, while EVA foam is made of ethylene vinyl acetate copolymer foam.

Density: XPE foam is generally denser and heavier than EVA foam.

Thickness: XPE foam is often thinner than EVA foam, but still provides good cushioning and shock absorption.

Water Absorption: XPE foam has low water absorption properties, while EVA foam can absorb water.

Durability: EVA foam is more durable than XPE foam, and is able to withstand repeated impacts and compression better.

Cost: XPE foam is usually more expensive than EVA foam due to its higher density and manufacturing process.

Both XPE foam and EVA foam can be recycled, but the recycling process may vary depending on the specific type and manufacturer.

In terms of being non-toxic and odorless, both XPE foam and EVA foam are generally considered safe for use. However, it’s important to note that some EVA manufacturers may use chemicals or additives in their foam production process that could potentially be harmful.

When it comes to environmental friendliness, XPE foam is generally considered more eco-friendly because it requires less energy to produce than EVA foam. XPE foam is also more resistant to moisture and temperature changes, which can make it last longer and reduce waste over time, further reducing its environmental impact.

Overall, both XPE foam and EVA foam have their own unique properties and benefits, and the choice between them may depend on the specific application and use case.

For more details of XPE foam, please visit:

CTF FOAM FOR AUTOMOTIVE

CAR INTERIOR ENVIRONMENTAL PROTECTION MATERIAL

1. Sound damping material for car door panels

Material:XPE,Flip Flop Foam

Density: 8B (125 kg/m & sup3;), 10B (100 kg/m & sup3;), 15B (66 kg/m & sup3;), 20B (50 kg/m & sup3;)

Thickness: 2mm 3mm 4mm

Application: Waterproof strip door, water repellent film

Processing Method: training be vacuum thermic

Advantages: the structure’s off foam closed cell provides ratio noise reduction and an excellent waterproof property.

2. material acoustic for flooring

Material:XPE,Flip Flop Foam

Density: 10B (100 kg/m & sup3;), 15B (66 kg/m & sup3;)

Thickness: 5mm 6mm 7mm

Processing Method: pressing for warmth and needlework

Advantages: it is used in the middle layer flooring car. The most common is the Combination product from PVC material. Easy Processing and laminar with others material to improve the waterproof properties and Insulation.

3. Material car sunshade board motorcar

Material:XPE,Flip Flop Foam

Density: 20B (50 kg/m & sup3;), 25B (40 kg/m & sup3;), 30B (33 kg/m & sup3;)

Thickness: 5mm

Processing Method: Press for warmth

Advantages: excellent material’s isolation and building properties.

4. Pad damping for trunk of car

Material:Flip Flop,XPE Foam

Density: 30B (33 kg/m & sup3;), 35B (28 kg/m & sup3;)

Thickness: 3mm, earrings for cabochon, 12mm earrings, gifts for her, mm stud earrings 6mm

Processing Method: Press for warmth

Advantages: extremely easy to whittle in size you want protected SHOCKPROOF and properties ratio noise reduction.

5. Vibration dampening material for ceiling of car

Material:Flip Flop& Iexcl; IXPP foam

Density: 15B (66 kg/m & sup3;)

Thickness: 4mm 5mm

Processing Method: pressing for warmth and die cut

Advantage: processing with flexibilityFlip FlopOr off foam material IXPP to prevent vibration and reduce the warmth.

6. Thermal insulation and sound proofing material for car

Material:XPE foam

Density: 30B (33 kg/m & sup3;)

Thickness: 3mm, earrings for cabochon, 12mm earrings, gifts for her, mm stud earrings

Processing Method: Adhesive (included)

Advantages: Espuma adhesive for an easy reduction, good furniture soundproof and heat insulation performance. Flame retardant available.

Closed cell PE foam For Surf board

Cross linked Polyethylene foam is closed cell, meaning it consists of cells so tightly packed together that it gives the appearance of one uniform structure.

CTF foam for surfboard /bodyboard material

Foam Name : IXPE foam

Type: Closed cell irradiation crosslinked polyethylene foam

Recommended thickness : 4mm , 5mm

Ratio: 10Times, 15Times ; Density: 100Kg/m3, 66Kg/m3

IXPP new material for automotive interior

There are two kinds of plastics commonly used in automobile interiors: general plastics (PVC, PE, PP) and engineering plastics (PA, ABS, PC). The current PE material has poor weather resistance and is not suitable for the environment.

Force-sensitive, easy to age, heat resistance is not ideal, low-density poly-Zene materials are used at 80°C, and high-density poly-Zene materials are used at 110°C.

For the lightweight of summation materials, IXPP was developed along the way.

IXPP is formed by mixing and extruding polypropylene (PP), AC foaming agent, etc., irradiated by an electron accelerator, and foamed at high temperature.

IXPP performance:

Has good thermal stability (use temperature up to 130°C);

Has good mechanical properties such as toughness, tensile strength, impact strength; IXPP material is environmentally friendly and low VOC (with industry test reports).

The main application of IXPP:

Dashboards, door panels, consoles, decorative surfaces,

IXPP material advantages: 60% lighter than ordinary materials, PP foam material CO2 index improved by more than 40% compared to PVC foam material; suitable for thermal stability up to 120°C

high processing technology and processing efficiency; compared with TPO foam, it has better scratch resistance and compression recovery.

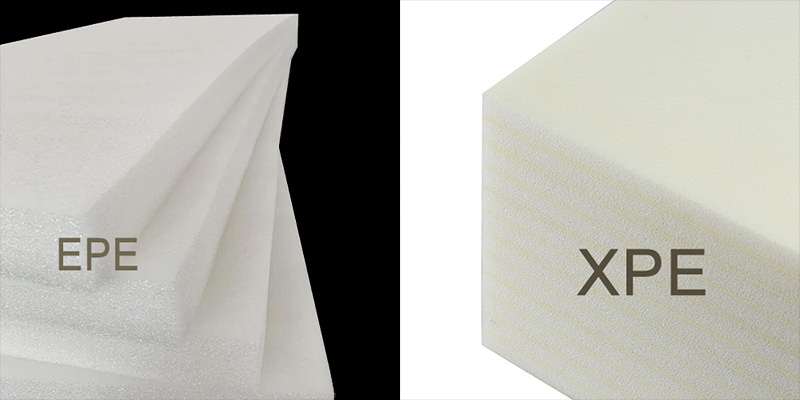

The difference between XPE/IXPE foam and EPE foam

Material: XPE foam (cross-linked polyethylene foam) and EPE foam (expanded polyethylene foam) are both made from polyethylene, but they have different properties due to differences in the manufacturing process.

Density: XPE foam has a higher density than EPE foam, which makes it more durable and better at absorbing impact. It is therefore often used in protective packaging, sports equipment, and insulation.

Thickness: EPE foam is available in thicker sizes than XPE foam, which makes it suitable for applications where thicker padding is required, such as in cushioning for furniture and mattresses.

Water resistance: XPE foam is waterproof, whereas EPE foam is water-resistant. This means that XPE foam is better suited for outdoor applications or for use in wet environments.

Cost:The price of EPE material is relatively cheap. Therefore, it is widely used. In daily life, we can often see the figure of foam: such as the packaging of fragile gifts such as wine, the inner packaging of hardware products, toys, melons and fruits, and leather shoes. In addition, foam is also widely used in car seat cushions, pillows, electronic appliances, instrumentation, computers, audio, medical equipment, industrial control chassis, hardware lighting, handicrafts, glass, ceramics, home appliances, spraying, furniture furniture, daily necessities, etc. product packaging.

What is XPE/IXPE foam?

XPE foam and IXPE foam are new environmentally friendly polymer materials, safe, non-toxic and tasteless. Compared with EPE foam, XPE and IXPE foam materials have better mechanical properties, are stronger, more durable, and have excellent moisture-proof, thermal insulation and sound insulation effects. XPE foam is commonly used in construction, automotive, sports, packaging and air conditioning industries, such as floor sound insulation mats, floor moisture-proof mats, baby crawling mats, etc.

Which is better, XPE foam or EPE foam?

Compared with price, EPE has more advantages;In terms of physical properties, the parameters of various mechanical properties of XPE foam materials are better;According to the grade of material, XPE foam material is more high-grade;In the packaging industry, as the inner material for product packaging, EPE and XPE have their own advantages and disadvantages. Based on production cost considerations, EPE is more widely used, but in order to improve the quality of packaging, many customers have chosen XPE to fit foam. approach that combines the advantages of both.

Closed cell PE foam, Cross linked polyolefin foam, Chemical cross linked foam, Irradiated cross linked foam, China Manufacturer, Factory price, Fast delivery.

How to distinguish XPE and EPE? What is the most intuitive difference between XPE and EPE?

The cells of XPE foam are more delicate and uniform than those of EPE. The cells of EPE foam are often relatively large, and the size of the cells is uneven. For the thicker version of 15mm and 20mm children’s crawling pads, there is another way to distinguish: foam does not need to be fitted, while XPE foam must be double-layered – XPE foam is limited by technology and equipment. The thickness of the thickest XPE material is about 10mm, so the thickened version of the XPE children’s crawling mat is usually realized by high-temperature double-layer bonding. On the side of the thickened version of the crawling mat, careful observation can see the traces of the bonding.

CYG TEFA CO.,LTD. established in December of 2002. We are committed to developing. manufacturing, selling cross-linked PE foam. Now we have 3 production bases in Shenzhen, Hangzhou, Chongqing, 21 production lines of all kinds, with annual production capacity of 15000 tons; Our main products: XPE,IXPE,IXPP,ESD foam, and various types composite materials based on XPE & IXPE; Widely used in automobile, air conditioning and refrigeration, construction, sports safety equipment, medical supplies, ESD packaging for electronic products, etc. Our products are sold in many countries of the world.

Full range of thicknesses and densities waiting for you.

Welcome Contact us to get the right foam material.

Trust you will find the satisfying solution here.

Compare Polyvinyl hloride, Polyethylene to Cross-linked Polyethylene

Polyethylene is referred to as PE, which is a polymer of ethylene and is non-toxic. Easy to color, good chemical stability, cold resistance, radiation resistance, good electrical insulation.

Polyvinyl chloride, referred to as PVC, is a polymer of vinyl chloride. It has good chemical stability and is resistant to acid, alkali and some chemicals. It is moisture-resistant, aging-resistant and flame-retardant. It should not be used above 60°C, and it will harden at low temperatures. Polyvinyl chloride is divided into soft plastics and hard plastics.

Cross-linked polyethylene, referred to as XLPE, is an important technology to improve the performance of PE. The performance of PE modified by crosslinking can be greatly improved, which not only significantly improves the mechanical properties, environmental stress cracking resistance, chemical corrosion resistance, creep resistance and electrical properties of PE, but also The temperature resistance level has been significantly improved, and the heat resistance temperature of PE can be increased from 70 ° C to more than 90 ° C, thus greatly broadening the application range of PE. At present, cross-linked polyethylene (XLPE) has been widely used in pipes, films, wire and cable materials and foam products.

CYG TEFA’s foam products are made of cross-linked polyethylene (XLPE Foam), which is better than PVC and PE foam.