The difference between XPE/IXPE foam and EPE foam

Material: XPE foam (cross-linked polyethylene foam) and EPE foam (expanded polyethylene foam) are both made from polyethylene, but they have different properties due to differences in the manufacturing process.

Density: XPE foam has a higher density than EPE foam, which makes it more durable and better at absorbing impact. It is therefore often used in protective packaging, sports equipment, and insulation.

Thickness: EPE foam is available in thicker sizes than XPE foam, which makes it suitable for applications where thicker padding is required, such as in cushioning for furniture and mattresses.

Water resistance: XPE foam is waterproof, whereas EPE foam is water-resistant. This means that XPE foam is better suited for outdoor applications or for use in wet environments.

Cost:The price of EPE material is relatively cheap. Therefore, it is widely used. In daily life, we can often see the figure of foam: such as the packaging of fragile gifts such as wine, the inner packaging of hardware products, toys, melons and fruits, and leather shoes. In addition, foam is also widely used in car seat cushions, pillows, electronic appliances, instrumentation, computers, audio, medical equipment, industrial control chassis, hardware lighting, handicrafts, glass, ceramics, home appliances, spraying, furniture furniture, daily necessities, etc. product packaging.

What is XPE/IXPE foam?

XPE foam and IXPE foam are new environmentally friendly polymer materials, safe, non-toxic and tasteless. Compared with EPE foam, XPE and IXPE foam materials have better mechanical properties, are stronger, more durable, and have excellent moisture-proof, thermal insulation and sound insulation effects. XPE foam is commonly used in construction, automotive, sports, packaging and air conditioning industries, such as floor sound insulation mats, floor moisture-proof mats, baby crawling mats, etc.

Which is better, XPE foam or EPE foam?

Compared with price, EPE has more advantages;In terms of physical properties, the parameters of various mechanical properties of XPE foam materials are better;According to the grade of material, XPE foam material is more high-grade;In the packaging industry, as the inner material for product packaging, EPE and XPE have their own advantages and disadvantages. Based on production cost considerations, EPE is more widely used, but in order to improve the quality of packaging, many customers have chosen XPE to fit foam. approach that combines the advantages of both.

Closed cell PE foam, Cross linked polyolefin foam, Chemical cross linked foam, Irradiated cross linked foam, China Manufacturer, Factory price, Fast delivery.

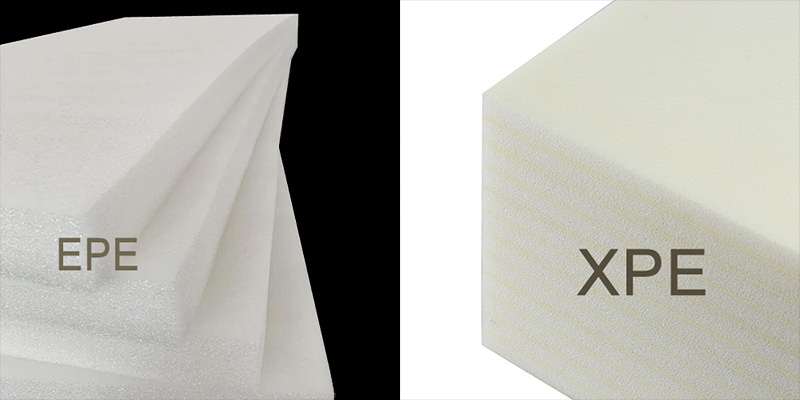

How to distinguish XPE and EPE? What is the most intuitive difference between XPE and EPE?

The cells of XPE foam are more delicate and uniform than those of EPE. The cells of EPE foam are often relatively large, and the size of the cells is uneven. For the thicker version of 15mm and 20mm children’s crawling pads, there is another way to distinguish: foam does not need to be fitted, while XPE foam must be double-layered – XPE foam is limited by technology and equipment. The thickness of the thickest XPE material is about 10mm, so the thickened version of the XPE children’s crawling mat is usually realized by high-temperature double-layer bonding. On the side of the thickened version of the crawling mat, careful observation can see the traces of the bonding.

CYG TEFA CO.,LTD. established in December of 2002. We are committed to developing. manufacturing, selling cross-linked PE foam. Now we have 3 production bases in Shenzhen, Hangzhou, Chongqing, 21 production lines of all kinds, with annual production capacity of 15000 tons; Our main products: XPE,IXPE,IXPP,ESD foam, and various types composite materials based on XPE & IXPE; Widely used in automobile, air conditioning and refrigeration, construction, sports safety equipment, medical supplies, ESD packaging for electronic products, etc. Our products are sold in many countries of the world.

Full range of thicknesses and densities waiting for you.

Welcome Contact us to get the right foam material.

Trust you will find the satisfying solution here.